Digital Special Aluminum Plastic Film

Keywords:

Digital Special Aluminum Plastic Film

Product Description

Product introduction

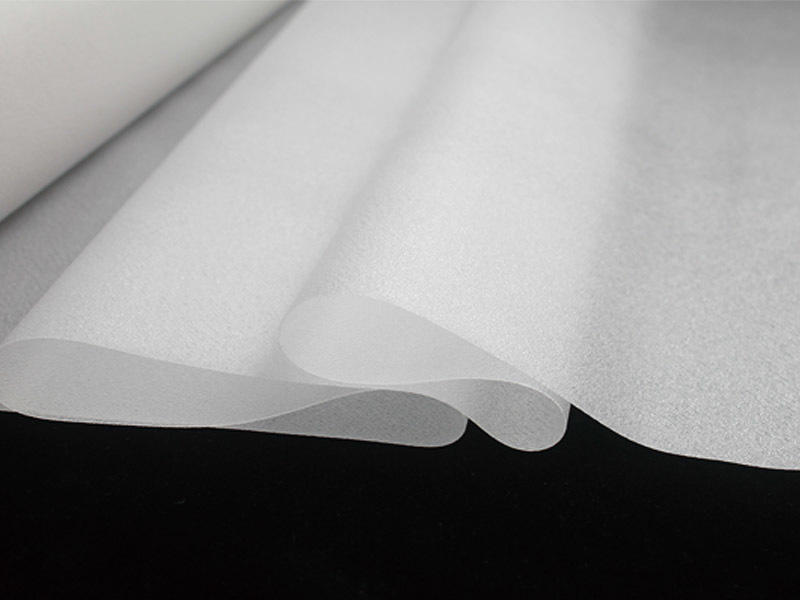

The EV-113NC aluminum-plastic film’s thickness is controlled in the range of 113±3%μm,it has excellent ductility and electrolyte resistance which has high composite strength and excellent package performance. The special protective layer still has the ability of self-repairing after stretching through stamping, which provides stable and long-term protection for the inner layer of the aluminum-plastic film.Among them, EV-113NC has the remarkable advantages of no rolling, powder dropping and bottom leakage.

Technical Data Sheet

Product performance advantage:

|

Superior point |

Superior description |

|

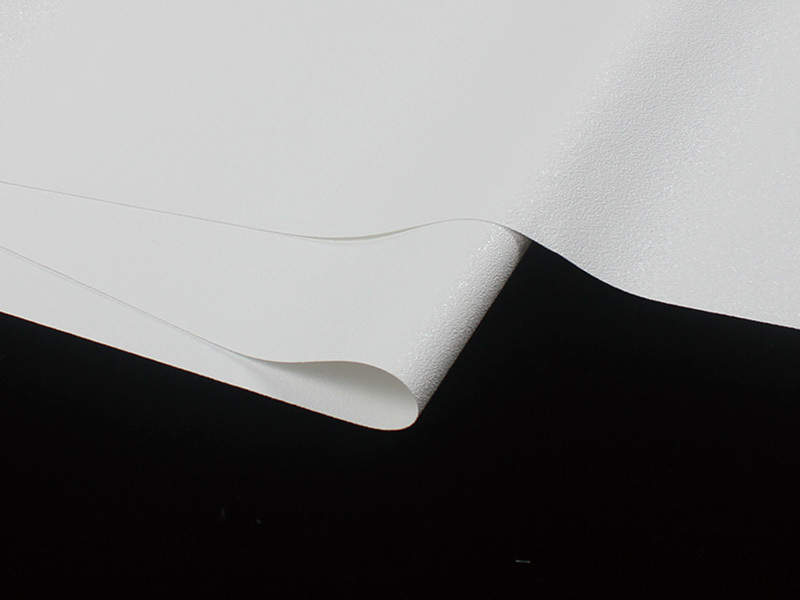

No rolling |

( After automatic shell punching ,Aluminum plastic film,the film is flat and non-adsorptive, is conducive to vacuum adsorption, completely satisfied with automatic production, but also can meet the manual collection and arranging, convenient for the late top side sealing packaging, greatly improve the production efficiency and quality) |

|

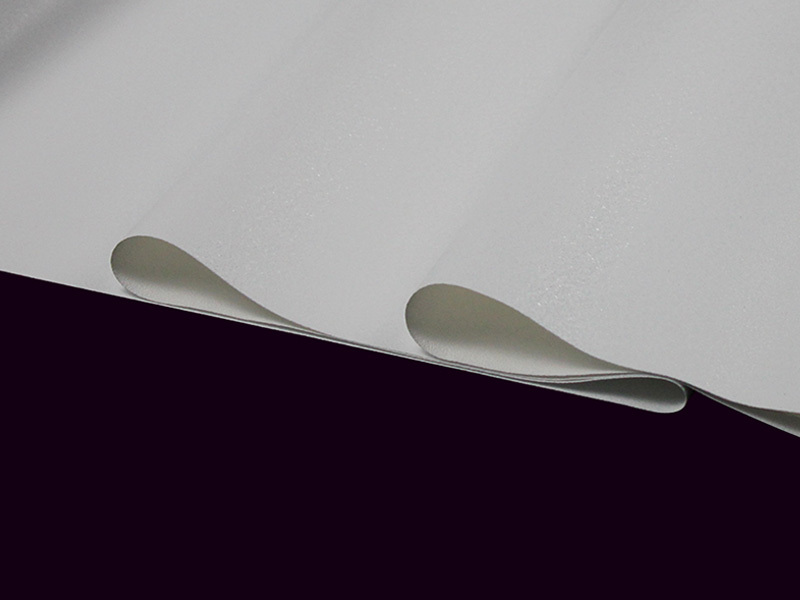

NO powder dropping |

(Our aluminum plastic film using special processing process, make the product in the process of shell punching, the surface of the mold will not be stained with powder due to the dropping powder of aluminum-plastic film. Thus reduce the time of mold cleaning, at the same time improve the quality of customer production (According to the statistics of the customer on the spot, the powdered aluminum-plastic film needs to be cleaned every half an hour, and it takes 10 minutes at a time.)) |

|

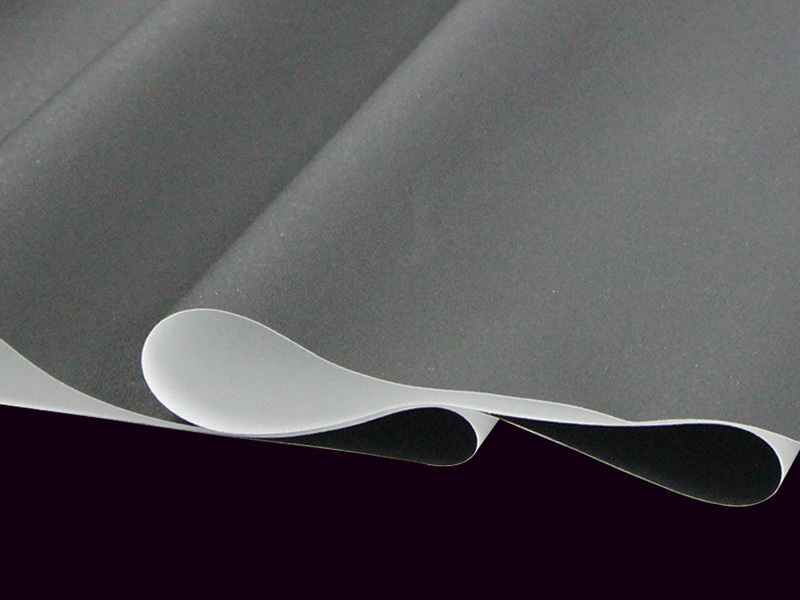

Evenly hot sealing |

Hot sealing after the melt glue effect, aluminum plastic film in the normal packaging inspection, our aluminum plastic film on both side is evenly milky white, not biased to one side, no aluminum leakage, can eliminate the risk of poor packaging. |

Regular performance:

|

Tested Items |

Unit |

Measured Terformance index |

Tested Method |

|

Thickness |

μm |

113±3% |

GB/T6672-2001 |

|

Peeling strength |

N/15mm |

≥5 |

GB/T8808-1988 |

|

Peeling strength |

N/15mm |

≥15 |

GB/T8808-1988 |

|

Thermal sealing strength(CPP/CPP) |

N/15mm |

≥100 |

QB/T2358-1998 |

|

Friction factor |

/ |

PA/PA≤0.40 |

GB/T10006-2021 |

|

CPP/CPP≤0.40 |

|||

|

Perpuncture performance |

N |

≥23 |

GB/T10004-2008 |

|

High temperature and humidity |

/ |

No stratification |

85℃,95%RH,7d |

|

ROHS |

/ |

ROHS |

Third-party authority |

|

REACH |

/ |

REACH |

Third-party authority |

|

SVHC |

/ |

SVHC |

Third-party authority |

Previous page

Next page

Recommended Products

Welcome Your Message

![[Official Account] [Official Account]](https://omo-oss-image.thefastimg.com/portal-saas/new2022111413013655697/cms/image/c4c29737-250e-47b0-bf2c-672ebe8c830d.png)